Home ♦

Balers and wrappers

KUHN balers and wrappers are dedicated to their purpose; baling and wrapping without compromises. Field performance, bale density and crop quality are fundamental to the profitability of every baling and wrapping operation. The unique features and innovations like the INTELLIWRAP and e-TWIN wrapping technologies and the TWINPACT double plunger system make a real difference.

KUHN offers the most efficient and versatile range of balers and wrappers available for the market to suit your demands.

Your benefits

Your benefits

An intake system that can handle every crop condition

The FB 3135 fixed chamber round baler is designed to provide you the highest capacity in the toughest conditions across the world. To better meet your operation's specific needs, there are two intake options available. Choose one of our INTEGRAL ROTORS: the 14- or 23-knife OPTICUT cutting rotor.

Perfect bale formation

The redesigned heart of the baler consists of 18 POWERTRACK rollers. The rollers have symmetrical profiles which generate exceptionally high density and reliable bale rotation in all crop conditions. Moreover, several smart tailgate features enable optimum bale shape and density.

Secure binding solutions

One of the final steps in creating the perfect bale is the binding. It is one of the most crucial steps! KUHN binding solutions guarantee reliable and secure net binding. All FB models can be equipped with a combination of twine and net binding.

Videos

View videos

Your benefits

Your benefits

Optimal performance, day after day

Built for high-volume baling, the VB 3165 and 3195 feature heavy-duty components to keep you producing rock-hard bales, bale after bale, day after day. To better meet your operation's specific needs, there are two intake options available. Select one of our three INTEGRAL ROTORS: the non-cutting OPTIFEED rotor or the 14- and 23-knife OPTICUT cutting rotors.

Consistent, firm round bales

The VB 3165 and 3195 models are designed to work in the toughest conditions across the world and are ideal for custom operators who need extra density in straw. The PROGRESSIVE DENSITY system increases tension as the bale grows, providing a firm bale with a tough outer shell.

Secure binding solutions

One of the final steps in creating the perfect bale is the binding. It is one of the most crucial steps! KUHN binding solutions guarantee reliable and secure net binding. The net binder with active stretch technology ensures a firm bale shape with constant net tension throughout the entire binding cycle. When required, VB balers can be equipped with a combination of twine and net binding.

Videos

View videos

Your benefits

Your benefits

Ultra compact and lightweight

With its low weight and excellent manoeuvrability, the KUHN i-BIO+ offers you outstanding performances in hilly conditions and in small or wet fields with narrow access gates.

Consistent, firm round bales

For compressing the crop into consistent size and dense bales, the baling process has to be as effective as possible, while being gentle on the crop. The bale chamber of the i-BIO+ consists of 18 rollers with POWERTRACK profile for reliable bale rotation.

Excellent wrapping & binding

The i-BIO+ features our unique TWIN-reel film binding and INTELLIWRAP systems. The TWIN-reel film binding system maximises your silage quality and offers you additional advantages by means of costs, recycling, ease of operation and storage. INTELLIWRAP offers greater management and control of the wrapping process by continuously monitoring the wrapping process.

Videos

View videos

Your benefits

Your benefits

Excellent wrapping & binding

The KUHN FBP 3135 Fixed Chamber BalePack offers you high-quality bales at the lowest costs. The patented KUHN TWIN-reel film binding system reduces the film binding cost by 30%. A perfect bale seal for high-quality bale conservation is created when combining film binding with both 3D wrapping and INTELLIWRAP.

Optimal crop intake to meet your capacity needs

The cam steered pick-up on the FBP 3135 maximizes the full capacity of the machine. With a working width of 230 cm, the machine is capable of working in all windrows and will not let you down, even in the toughest conditions. Choose one of our INTEGRAL ROTORS: the 14- knife or 23-knife OPTICUT cutting rotor. Both the rotor disengagement and DROPFLOOR technology ensures a fast clearance in case of a blockage and enables you to quickly continue your baling operation.

Consistent, firm round bales

A consistenly filled bale represents quality in every form. Perfect, firm, round bales represent less air in the bale, resulting in high-quality feed! The redesigned bale chamber of the FBP 3135 consists of 18 POWERTRACK rollers which generate an exceptionally high density and reliable bale rotation in all crop conditions. The unique fast tailgate detection system guarantees an optimal bale shape and density.

Videos

View videos

Your benefits

Your benefits

The best results in a very broad range of crops

Fast and reliable bale transfer, combined with a high-speed, twin-satellite wrapping unit equipped with 3D wrapping and INTELLIWRAP, gives the KUHN VBP the possibility to optimize the wrapping for each crop condition and therewith maximal flexibility.

Consistent, firm round bales

Perfectly shaped and dense bales are produced by the PROGRESSIVE DENSITY bale chamber. The system increases tension as the bale grows, providing a firm bale with a tough outer shell.

Optimal crop intake to meet your capacity needs

The pick-up on the VBP 3100 Series machines maximizes the full capacity of the machine. With a working width of 230 cm, the machine is capable of working in all windrows and will not let you down, even in the toughest conditions. Choose one of our INTEGRAL ROTORS: the 14- knife or 23-knife OPTICUT cutting rotor. Both the rotor disengagement and DROPFLOOR technology ensures a fast clearance in case of a blockage and enables you to quickly continue your baling operation.

Videos

View videos

LSB Series

Efficiency and profitability for your baling operation

Your benefits

Your benefits

Top quality bales in all crop conditions

All KUHN LSB Series balers feature POWER DENSITY, a unique pre-chamber system that ensures consistently filled flakes and results in heavy, square-edged bales regardless of the windrow condition.

On top of that, the LSB Series range consists of two extreme high-density balers: the LSB 1290 iD and the LSB 1270 DX. The LSB 1290 iD (intelligent-DENSITY) model is designed to produce 120 x 90 bales with up to 25% higher bale density than those made with a conventional large square baler. The patented TWINPACT double plunger system is the basis of this extreme high bale density whilst avoiding high peak loads on the machine. The LSB 1270 DX performs under all circumstances and provides you with the highest bale densities in the 120 x 70 segment.

Optimal crop intake to meet your capacity needs

The pick-up of the LSB models is designed to match the full capacity of the machine. With an intake width of 230 cm, the baler is capable of working in all swaths. The reliable cam track system will not let you down, even in the harshest conditions. To better meet your operation's specific needs, there are three intake options available. Select from one of our patented INTEGRAL ROTORS: the OPTIFEED non-cutting rotor, the 14-knife or the 23-knife OC cutting rotor.

Robust driveline and maximum security

The combination of synchronized gearboxes, drivelines and oversized chains is designed for maximum life and limited maintenance. The driveline layout is simple, clean, and easy to service and maintain while minimizing the overall number of moving parts. All main intake components of the KUHN LSB balers are fitted with a cam-type clutch. With this non-stop safety system you can unblock the machine from the operator seat. The pick-up, INTEGRAL ROTOR and feeder fork are protected with cam-type torque limiters, which are automatically activated in the event of an overload.

Videos

View videos

Your benefits

Your benefits

Non-stop, fully automatic wrapping

The innovative patented AUTOLOAD function provides non-stop fully automatic loading, wrapping and unloading of square and round bales without interference from the driver. AUTOLOAD detects approaching bales, automatically scans the length of the bale and sets the loading arms into pre-load position. The result: an increased overall capacity and a more ergonomic and stressless working environment.

Design features with you in mind

The SW 4014 is capable of wrapping large square, medium square and round bales up to 1500 kg. The smart design of the wrapper guarantees easy (un)loading of the bales, front- and backwards, even when dropped in hard-to-reach locations. The solid design with an incorporated hydraulic sliding frame, allows unique 'drive through' operation for easy bale loading, outstanding stability and unmatched visibility of the wrapping process.

Intelligent & high-speed wrapping

ISOBUS, combined with the INTELLIWRAP system provides excellent distribution of the film applied around each bale for maximum efficiency and increased silage quality. The twin-satellite design ensures high-speed wrapping.

Videos

View videos

Your benefits

Your benefits

Excellent, cost-efficient and high-speed wrapping

Does wrapping 100 bales per hour with 6 layers of film seem impossible? Not with the KUHN RW 1810 bale wrapper. With a 30% faster cycle time you can keep up with the fastest balers around.

Unique loading system

The unique loading system, with its long loading arm integrated in the wrapping table, allows the bale to gently roll onto the wrapping table without extra process steps. It makes the wrapper suitable for loading the heaviest bales up to 160 cm in diameter and 1400 kg.

Exceptional driver comfort

100% fully automatic loading, wrapping and unloading without having to press a button! The AUTOLOAD function provides high accurate loading, wrapping and unloading of the bale on the go. The RW 1810 is operated via the KUHN VT 30 terminal with PROCESS VIEW user interface.

Videos

View videos

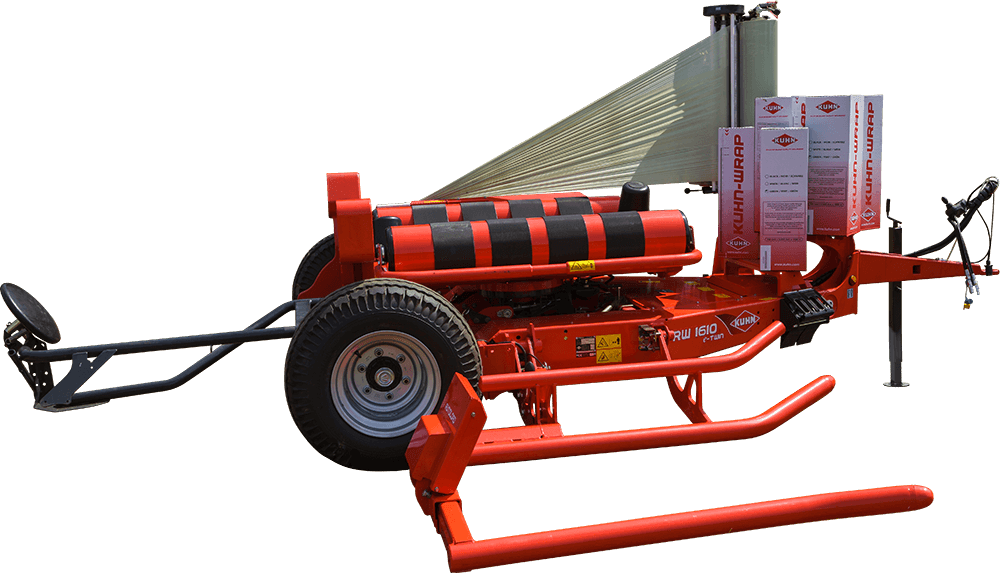

RW e-TWIN

Top quality, cost efficient and fast wrapping

Your benefits

Your benefits

Save 50% wrapping time

KUHN RW round bale wrappers can be equipped with the innovative e-TWIN technology for excellent, cost efficient and fast wrapping. Save up to 50% in wrapping time thanks to the positioning of the two dispensers delivering a larger surface of film with each rotation.

8% Film savings

Save up to 8% in film thanks to the unique pre-stretcher with film distribution. Calculate your exact savings depending on the bale size and number of film layers.

Tightly wrapped bales

For an increased airtightness and quality of feed.

Videos

View videos

Make savings in wrapping:

KUHN Wrappers

Film, Net and Twine Calculators

Check our KUHN Net, Film and Twine calculator to estimate your yearly volumes crop packaging products to be purchased.

RW –10 SERIES e-TWIN

e-Twin Calculator

Check out how e -TWIN technology can bring cost efficiency for your wrapping business.