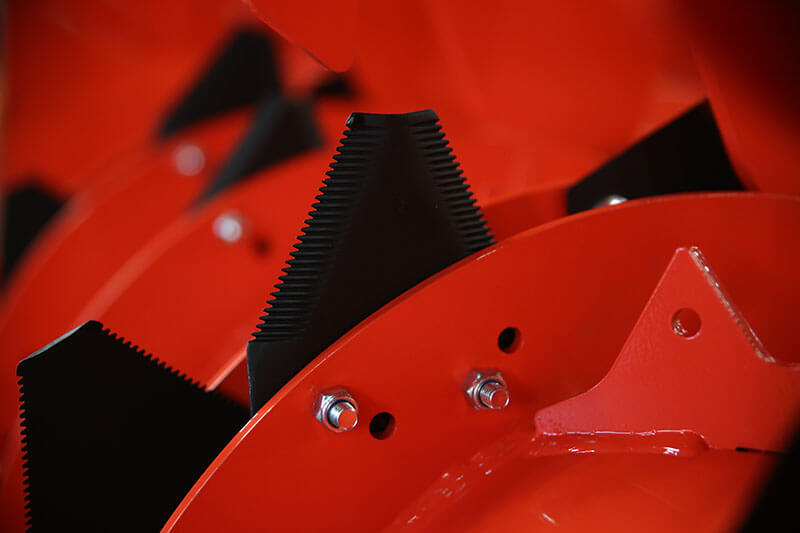

The steel, the thickness of the sections and the specially treated notched area provide the best compromise between hardness and resistance.

Triangular, straight, square or angled, the shape of the sections was specially studied to produce the best cut and to optimise loading.

Attachment by square-necked screw for easier replacement.

You’ll get the power you need for silage feeders, straw blowers and straw blowers & feeders from the sections linked to the beater’s drive system by POLYDRIVE® hydraulically disengageable belt.

Some sections are coated with tungsten carbide, the best compromise between wear resistance and impact resistance.

The steel and the specially treated notched area provide the best compromise between wear resistance and cut quality.

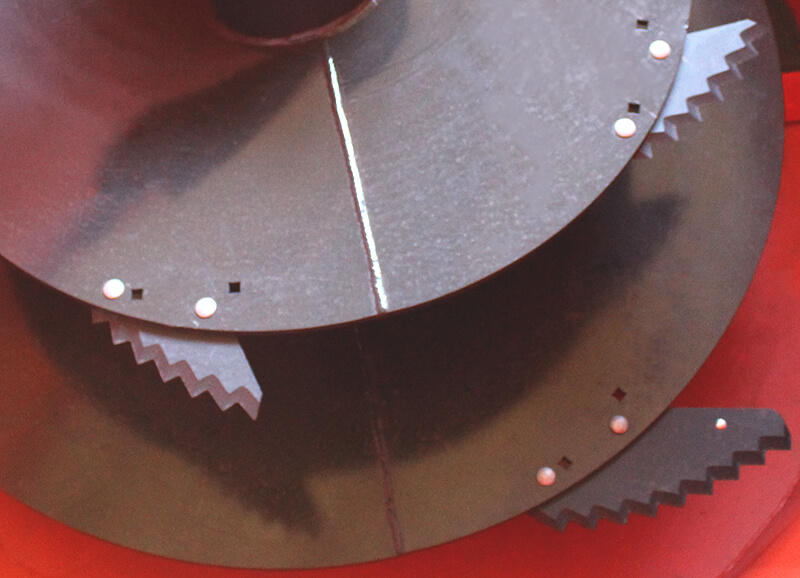

Long or short serrated knives are positioned on the auger for a drag-cut effect.

The asymmetrical notched area produces a clean cut and has a self-cleaning quality. The “swirl” effect is optimised by the last ¼ coil with double pitch.

The pitch angle is user-adjustable* according to knife position on the auger:

“Whole bale” position: Knives in attack position for faster bale break up.

“Economical” position: Retracted position for lower power requirement.

*On some mixer wagons models

Some knives can be coated with tungsten carbide: smooth surface and even harder than tungsten carbide resulting in lower power requirement and cleaner cut with forage that doesn’t stick.

The shape of the 4 cast iron drive wheels improves guidance and resistance to wear from the weight of bales on the chains.

Would you like to have more information?

Find a dealer