The seeding parts are manufactured with high-precision quality. This is essential for functionality and to optimise seeding efficiency.

A Ni-hard cast iron manufacturing process is used for some share models. This increases lifespan and cost-effectiveness due to the exceptional hardness of the material.

Shares are of optimal shape contributing to the regular delivery of seeds into the furrow.

Conventional shares have a simple and economical system of sowing. Maintenance costs are lower, seeding depth is regular and easy to control, distribution is uniform, furrow smoothing is reduced in wet soil and there is no running over stones in stony soil.

Shin profile, share length, height and overall shape are the result of many trials in real conditions.

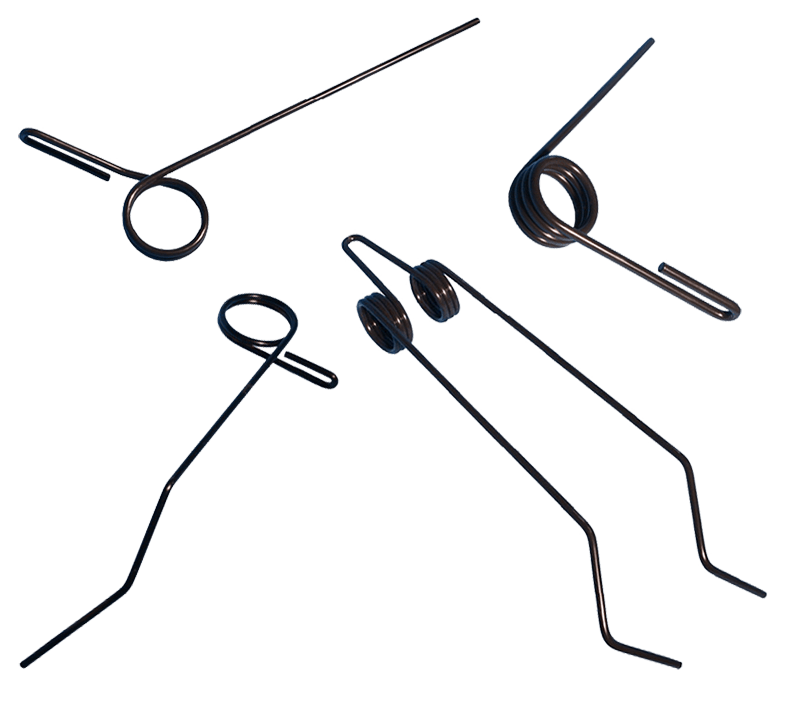

The covering tines have the same advantages as raking and tedding tines.

The steel used remains the best compromise between hardness (resistance to wear) and resilience.

Seeders, markers, openers, smooth, convex, notched or embossed; all discs are produced to ensure uniform, slower wear of parts.

Would you like to have more information?

Find a dealer