KUHN tines are made of special spring steel in different diameters: 8.5, 9.5 and 10.5mm.

Tines are fully shot-peened. This provides a resistance to the elastic range of 45 cm clearance. There is also a longer-life eye-fixing.

Powder paint is used for its better anti-corrosion qualities and increased tine life.

The gyrorakes tines have free coils that make KUHN tines flexible, efficient and harder wearing.

On gyrotedders, tines have an optimum 90° tine position thanks to the imprint in the GF’s arms. This enables an optimum forage pick-up.

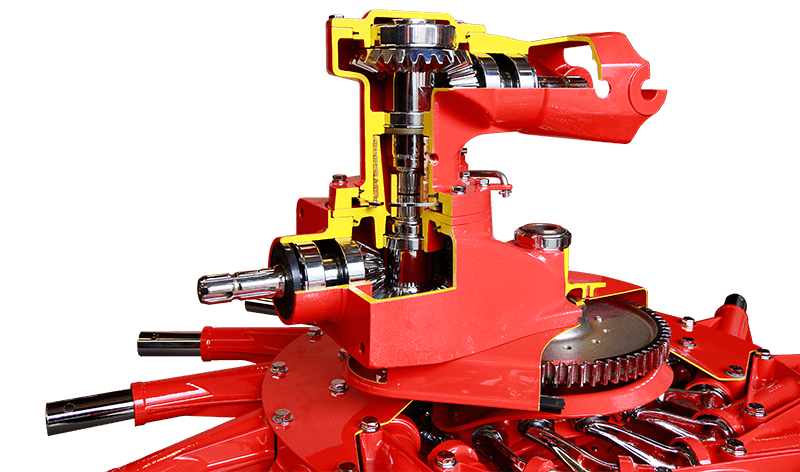

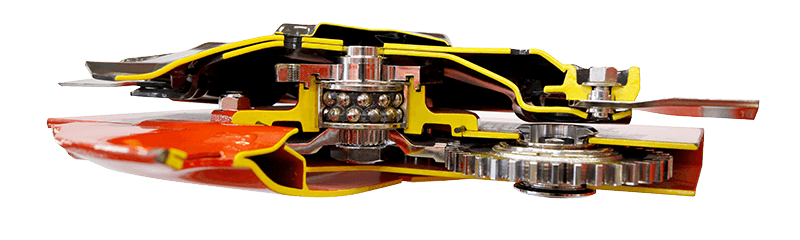

Kuhn has developed fully closed gearboxes that protect drive components completely for an increased resistance to wear. This design is what makes the MASTERDRIVE gearbox so successful, it guarantees exceptional reliability and service life even during intensive uses.

MASTERDRIVE

The DIGIDRIVE system consists of forged steel fingers, case-hardened for excellent wear resistance.

Minimum maintenance is required, as daily lubrication is not necessary.

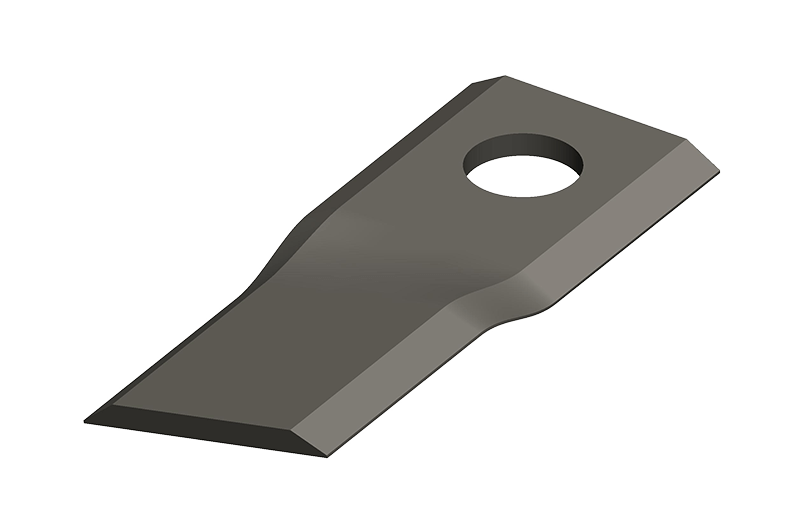

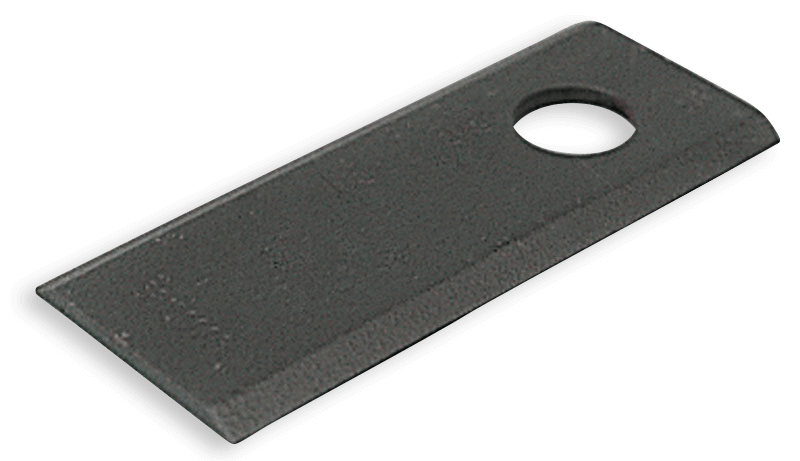

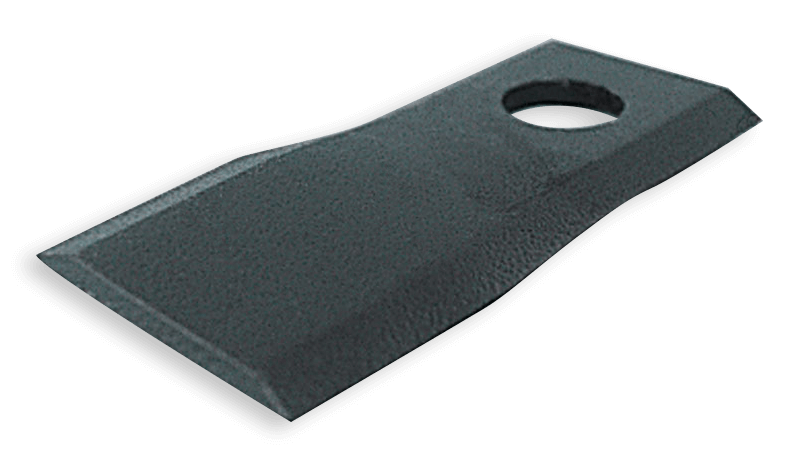

KUHN knives are subject to many stresses during operations. > 3.5mm thick knives can withstand a 45° deformation and < 3.5mm thick knives can withstand a 75° deformation without breaking or showing the slightest sign of cracking. Heat treatment is followed by painting and tempering which makes the knives more flexible. Knives are designed with the chamfer underneath to minimise stone damage to the cutting edge.

Available in Fast-Fit version, this system provides a certain number of advantages such as pre-stressed spring-loaded blades, grooved screws with shoulder to hold knives in place and support blades. The imprint in the skid prevents blade deformation except in one single zone.

Bolts can be replaced individually and at a minimum cost.

Each knife is designed for a special purpose:

The flat knife is self-sharpening.

The shape of the twisted knife creates a more aggressive cut.

The concave shape of the bent knife provides better resistance to deformation.

KUHN now offers a new thicker knife that has excellent anti-abrasion properties and increases service life by four to five times. It is highly resistant to deformation and is cheaper in terms of maintenance costs with its particularly favourable cost / lifespan ratio, not forgetting the savings in time spent.

It is designed with the chamfer underneath to minimise stone damage to the cutting edge.

KUHN OPTIDISC cutter-bar knives guarantee perfect forage flow and impeccable cut quality. With OPTIDISC technology, grass is cut once only. In order to achieve this, the distance between discs varies:

OPTIDISC technology

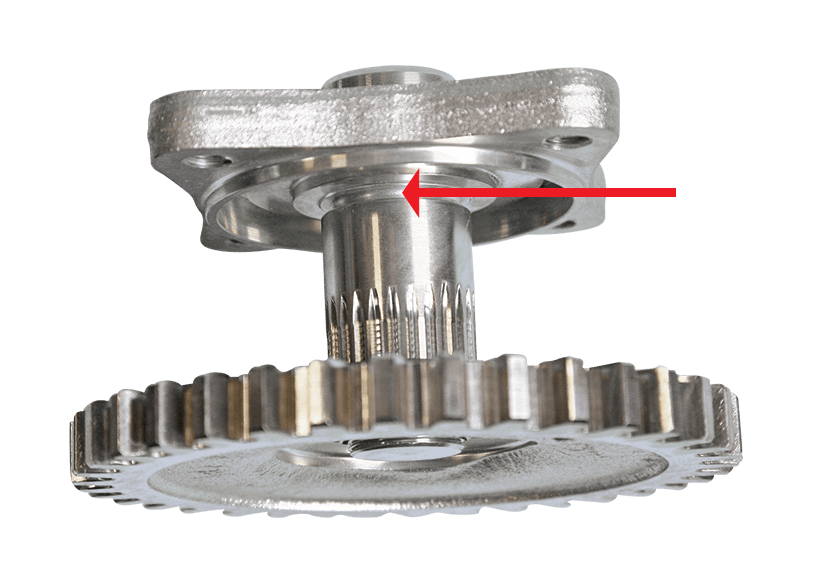

PROTECTADRIVE safety protects the cutter bar’s gear train. In the event of an impact with an obstacle, the disc shaft can shear just above the bearing thanks to a carefully dimensioned shear groove. Reparation costs and downtime are therefore reduced, with no subsequent damage to cutter bar.

PROTECTADRIVE safety

Would you like to have more information?

Find a dealer