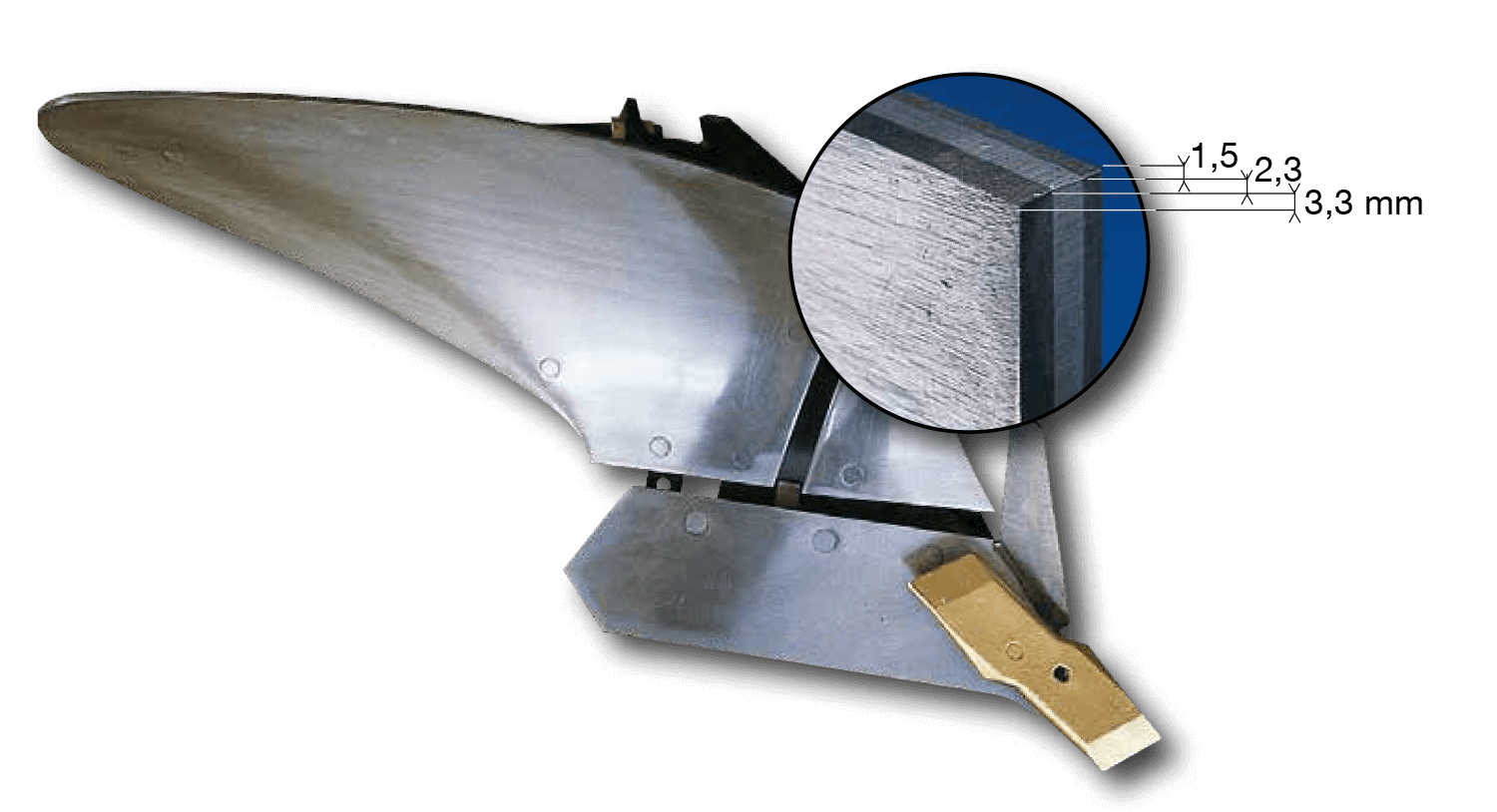

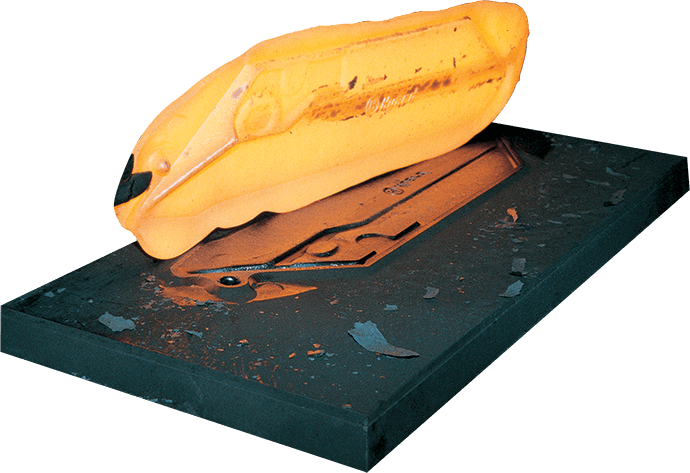

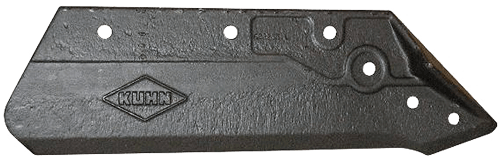

Cut in our plough factory, KUHN Triplex mouldboards and shins are more wear resistant because they have an extra thickness where it counts. Wear surfaces are 3.3mm thick for a longer life. Mouldboards are made of 3 unequal layers, unique to Kuhn.

The high and wide shin ensures great mouldboard and frog protection. The polished mouldboard improves output in difficult conditions such as clay.

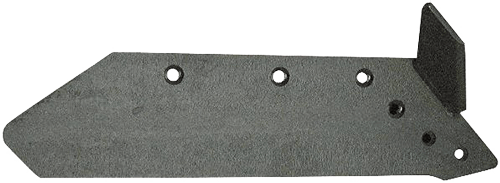

Different types of mouldboard and frog are available: Classic body: Helico-cylindrical, scandinavian helical, wide helical, american with blade, slatted, short or long cylindrical, diamond Bodies and RH helical Bodies.

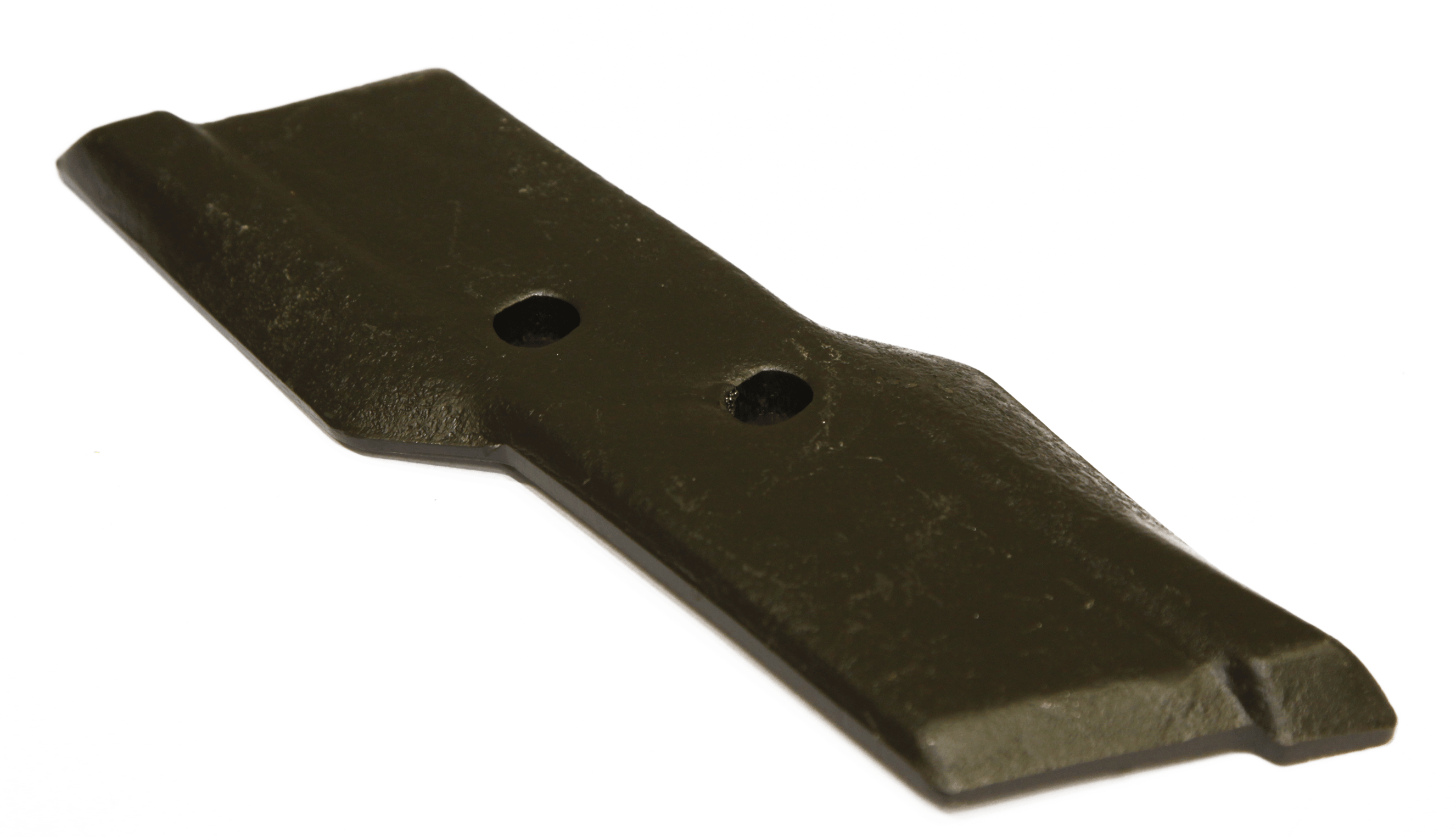

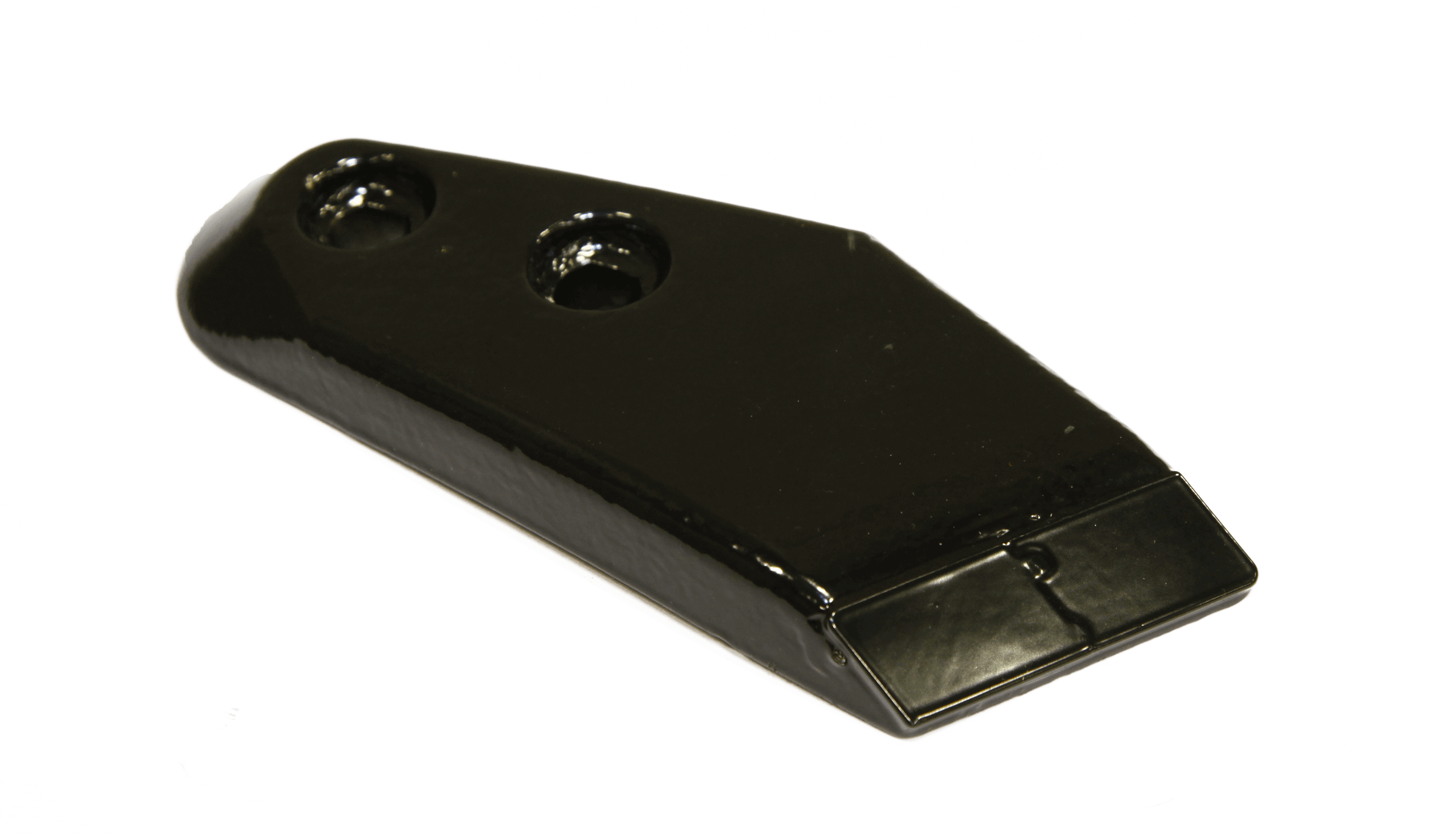

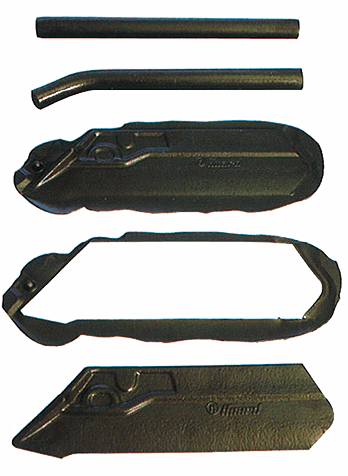

KUHN points are forged in a 1500-ton press at our plough factory. Mastery in drop-forging and heat treatment guarantee excellent wear resistance in any conditions. Material is concentrated in the high wear areas of the point.

On any terrain, uniform wear and fuel consumption are optimised by the shape of the points.

SEMI MARATHON point

MARATHON point

OLYMPIC point

KUHN shares are made from one piece material which keeps the original metal fibre structure and they undergo thermal treatment. This increases resistance to impacts and wear and preserves material fibre. They undergo the same drop-forging and heat treatment as points. This ensures a longer service life as well as manufacturing consistency

Shares are available with carbide plates. Carbide plates are thicker at the back of the share where most of the wear happens.

The forge-welded fin-coulter version protects the mouldboard shin and creates a cleaner furrow bottom, which produces better tractor adherence.

Would you like to have more information?

Find a dealer